Many customers arrive at our website or call us after having considered a number of options for their oil slops treatment. The standard for treating this waste is still to try and de-water using some kind of chemistry or blend the waste with oil solids and process through an energy intensive, slow thermal type of process.

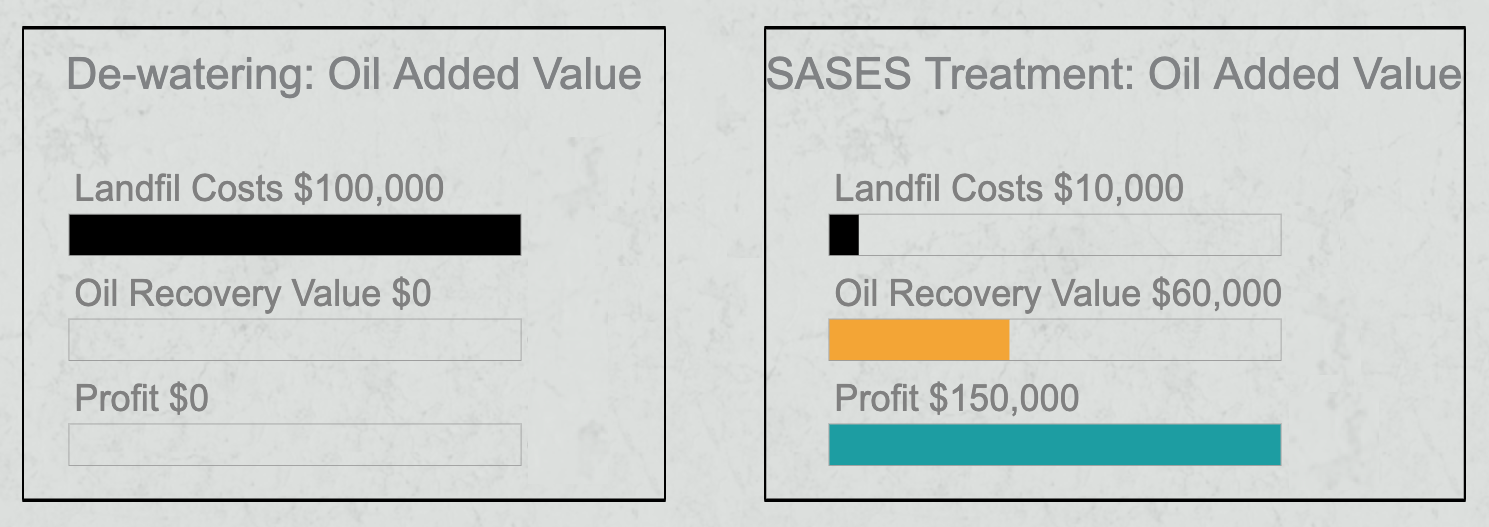

The difference between de-watering oil slops waste and genuine treatment using the SASES chemistry and process is fundamental and creates a completely new economy in waste management.

De-watering Drawbacks

De-watering only ever removes part of the water from the waste. At time this is very good quality water, however it concentrates the remaining water in a matrix consisting of solids, oil, chemicals and water. This resulting concentrated slurry or sludge is then very hard to treat. So, effectively removing part of the water has reduced the waste volume and now the remaining waste is much harder to process. Often landfill or thermal processing are the only realistic options available for this sludge.

In order to landfill the waste in many cases the sludge has to be stabilised or fixed and this approach doubles (sometimes triples) the total volume of the waste for transport and disposal. Thermal processing (often combined with drill cuttings) is energy intensive and slow.

SASES Oil Slops Treatment Three-way Split

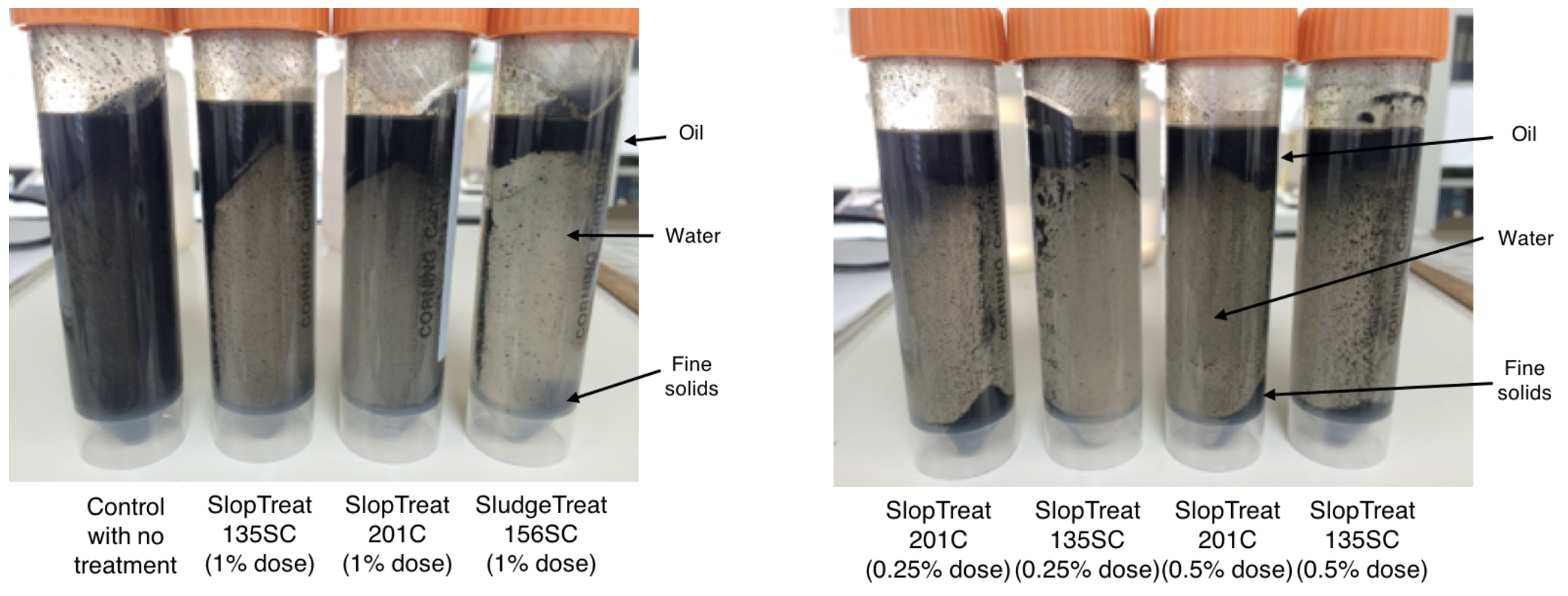

Our unique chemistry in comparison creates a three-way split between the oil, water and solids. This means oil is recovered with an economic value, all the water is recovered, and only dry solids remain for disposal to landfill or back to sea.

Let us use a simple example to illustrate the possible difference in operations.

There is 1,000 tons (or m³) of oil slops waste to be treated. This consists of 20% oil, 70% water and 10% solids. In a de-watering process this would look as the following: