SAS-ES Successfully Handles USA Oil Slops Treatment

/SAS-ES were supplied with a sample of oil slops waste (pictured right) from operations in Texas, USA where an effective chemical dosing and separation process was being sought. For this project, SAS-ES were set the task of maximising oil and solids recovery, so that the clean water fraction could be recovered for polishing and safe disposal via salt-water disposal wells. This would require SAS-ES products to effectively split the waste into three distinct phases of oil, water and solids, in order to maximise the recovery of clean oil, thus retaining a high water quality for disposal.

Here's how SAS-ES successfully dealt with this oil slops treatment project.

What we did...

Samples of the waste were dosed directly with different SAS-ES products, then shaken thoroughly for 30 seconds and spun in a spin out rotor centrifuge at 3,000rpm for 2 minutes. Gravity separation tests were also conducted and all testing was carried out at room temperature.

The results...

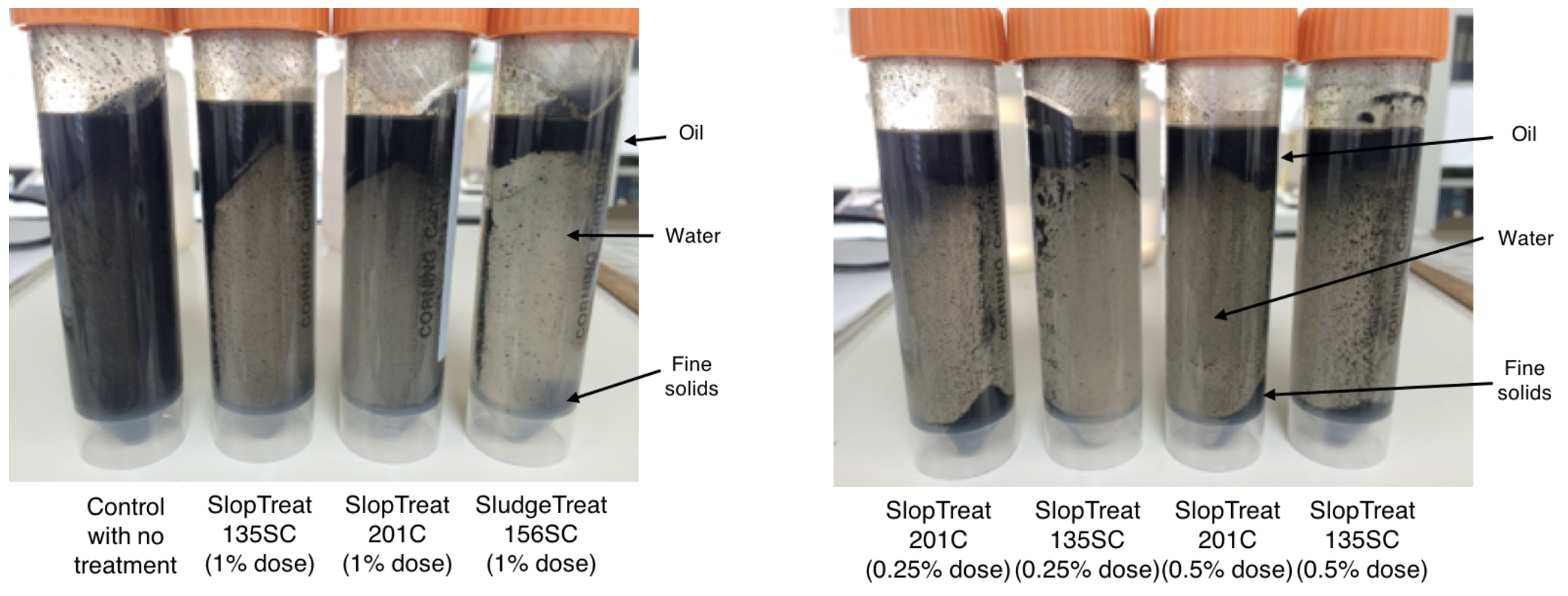

When the oil slop sample was treated with SAS-ES products there was a rapid and marked improvement in oil, water and solids separation was observed, and a higher quality water fraction was produced. Each product tested performed well, including our SAS SlopTreat products, which are the most cost effective and environmentally sound.

In the case of this oil slop sample, separation using gravity could be achieved in just 2 minutes! As shown in the picture below.

In the test when centrifugation was used, a clean separation was achieved to yield a clean water fraction for disposal, a clean oil phase on the surface and a fine solids fraction as a lower phase. As shown in the picture below.

So to sum up...

The SAS SlopTreat products have the ability to greatly enhance the treatment of the oil slop sample. Not only did SAS-ES enable faster separation, but we also enabled a cleaner and more efficient separation to take place allowing recovery of clean water, oil and solids phases.

It is clear without the SAS SlopTreat chemistry this waste sample would not readily separate and oil recovery would not be possible!