Tank Bottom Sludge Oil Recovery

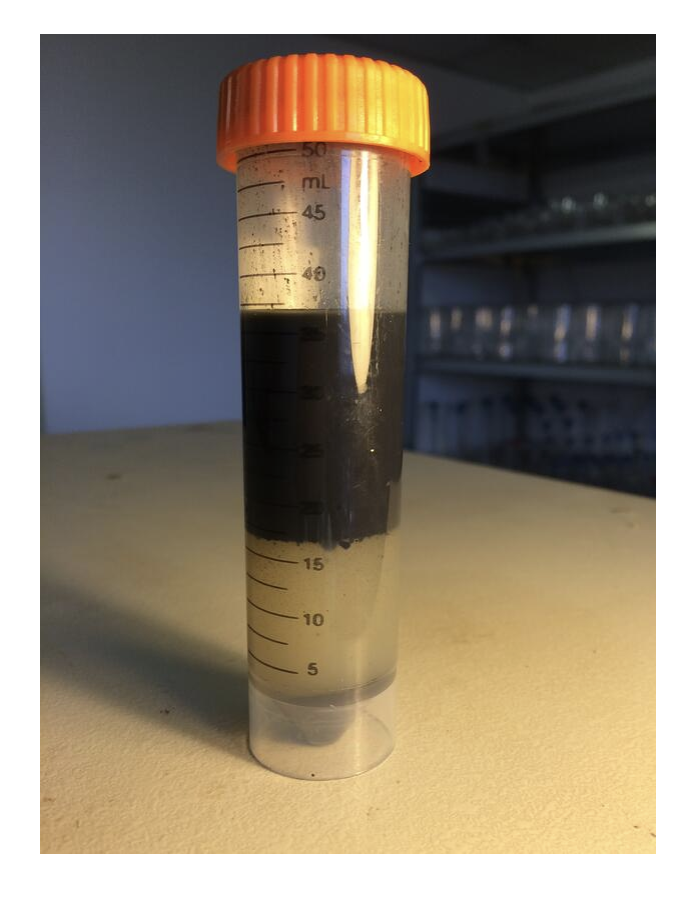

/SAS-ES receive many oil sludge waste samples, for this particular project the sample provided was black, oil coloured and contained a high oil content. The sample had been recovered from tank bottom sludge from a crude oil storage tank and sent to us by one of our customers to try and create a three-phase split of oil, water and solids.

What we did...

In order to successfully recover any oil present and remove as much of the water and sediment as possible, SAS-ES used a standard screening test method to reach the most effective result.

A sample of the waste was dosed directly with 0.5% of the SAS-ES products. Samples were then shaken thoroughly for 30 seconds and were spun in a spin out rotor centrifuge at 3,000rpm for 2 minutes. The samples were not diluted with water or any hydrocarbon solvent.

The results...

The testing provided different results for each product. However, it is clear the best result was obtained using the SAS SludgeTreat 156SC product, a further picture of this split is shown on the right.

So, to sum up...

After dosing the waste sample with our SAS SludgeTreat 156SC an immediate reduction in viscosity was observed. Our customer gained a significant oil recovery of 54%, with a clear water phase of 38%, meaning that solids only made up about 8% of the total waste stream.

Another successful oil sludge treatment process by SAS-ES!

Want to find out more about the SludgeTreat 156SC? Contact Us by clicking the button below.