Oil Sludge Treatment

For over 20 years SAS have provided our expertise to clients and partners to solve some of the most complex oil sludge waste problems. Starting with the Ineos refinery in Grangemouth, Scotland we have worked closely with waste management companies, refineries and contractors to turn oil sludge and other refinery waste into high grade crude oil, water and solids.

Oil Sludge in pits, lagoons and tanks often varies in in composition. This makes the design and implementation of successful treatment challenging and complex.

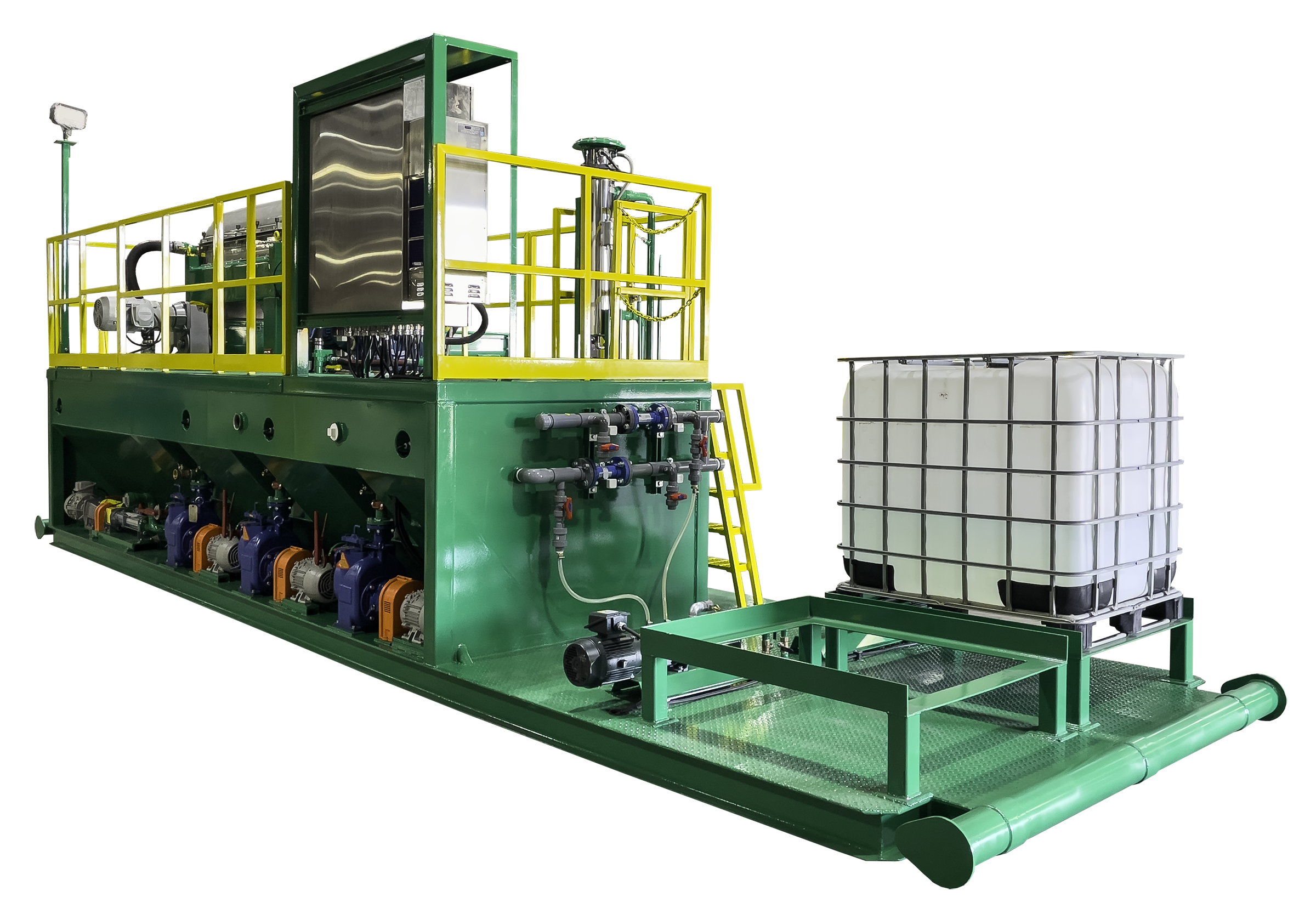

Our expertise, engineering, process and chemistry works together to provide robust, proven solutions that work on a wide range of oil sludge waste materials.

The SAS MIST process is capable of treating between 0.5 ton per hour and 50 ton per hour.

In combination with our waste blending module the SAS process delivers the results you need across a wide range of oil sludge waste

The SAS SludgeTreat Chemicals can be used with your existing decanter and tricanter equipment. SAS engineers are able to work with you to optimise your process.

The SAS process provides dry solids, recovered water and high quality recovered oil.

Our chemical production facilities are based in the UK, Houston, Texas, and in Saudi Arabia.